niponica is a web magazine that introduces modern Japan to people all over the world.

2019 NO.25

Japan’s Decorative Art of Urushi

Tradition and Innovation -

New Forms of the Decorative Art of Urushi

The world of urushi continues to experience expanding its potential as activity moves beyond traditional materials, products, and even applications.

See new forms of urushi art created through fusion with the latest technology and other fields.

1Urushi + incombustible materials

New technology has been developed for applying urushi to the surfaces of incombustible materials such as concrete. The company developed this technology independently to allow the application of urushi to surfaces other than those of wood and paper and to successfully impart natural warmth and visual variety to, normally inorganic, cold incombustible materials. The urushi coating also has excellent durability, waterproofness and antibiotic properties, so it is suitable for use in restaurants decoration. This technology produces an artistic building material that not only expands the application potential of urushi, but also opens new windows of opportunity in construction.

(Cooperation: Heisei Corporation)

・An island kitchen unit made of concrete coated with urushi.

・Urushi can be directly applied to the surfaces or to incombustible panels.

・Coated surfaces have an organic texture.

2Urushi + limestone

Smartphone cases individually hand-painted by shikki artisans from the Echizen area (Fukui Prefecture). The body of the case uses a new limestone-based material called "LIMEX."

LIMEX is environment-friendly in that it can be processed into a paper substitute with minimal consumption of water or timber and into a plastic substitute with fewer petroleum-derived materials. Currently, development of a tableware application is underway.

(Cooperation: "Traditional Crafts' Future Project", Keio University Graduate School of Media Design)

Patterns on the surfaces of the cases are inspired by local culinary such as soba noodles and traditional craft products such as eyeglasses of Sabae City, Fukui Prefecture (home of Echizen shikki) and the neighboring Echizen area.

3Urushi + 3D printers

Shikki produced by painting silicon onto a 3D printed mold, coating the resultant silicon mold with urushi, and then peeling off the urushi. This innovative artistic technique of urushi allows us to enjoy the luster and intrinsic beauty of urushi. New, never before seen urushi art. Using the latest technology, shikki need not be limited by constraints such as shapes and thickness and have extremely thin, free-form 3D surfaces.

(Cooperation: Kakuda Yota; Photograph: Yuu Kawakami, “SHIZUKU”)

* A 3D printer is a machine that builds up layers of a material such as resin based on design data to make a three-dimensional object.

4Urushi + outdoor goods

Urushi mugs with leather carry-strings at the bottom, designed to be hung from the waist or on a rucksack for easy transport. Taking advantage of the shikki characteristics of excellent robustness, waterproofness, and antibiotic properties as well as its ultra-lightweight, these mugs are ideal for use in outdoors situations, beyond conventional applications.

Being stackable, they help to save space when packing for camping trips. Artisans of Aizu-nuri (Fukushima Prefecture) produce each item by hand.

(Cooperation: Sekibikodo Co., Ltd. “NODATE mug”)

5Urushi + washi

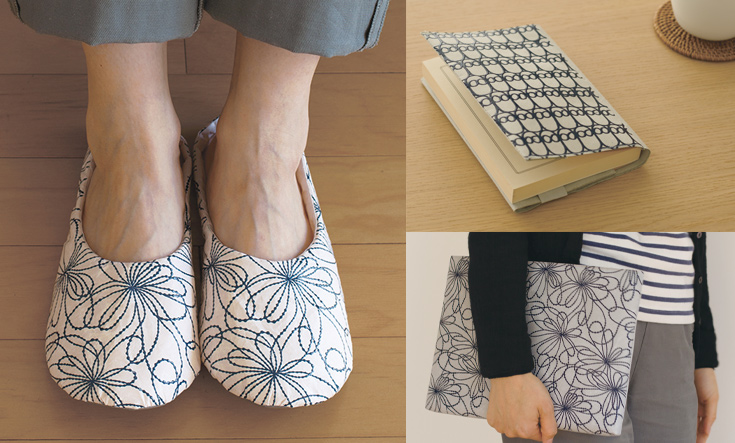

Slippers, book covers, bags etc. made of washi (Japanese traditional paper) printed with refined urushi patterns. By applying a special process to strong washi independently developed, by the company, urushi printing technology that was formerly applicable only to deerskin can also be applied to washi - enabling reproduction of beautiful, refined patterns. There is a wide variety of urushi patterns ranging from classic Japanese to contemporary designer styles. Skilled craftsmen print each sheet by hand.

(Cooperation: Onao Co., Ltd., “SIWA x URUSHI”)