niponica is a web magazine that introduces modern Japan to people all over the world.

2016 No.18

To read the e-book you need to have JavaScript enabled in your browser and a free Flash Player plug-in from Adobe Systems Inc. installed.

Amazing Paper in Japan

High-Tech Paper:

Bringing Convenience to People’s Lives

A helping hand for industry

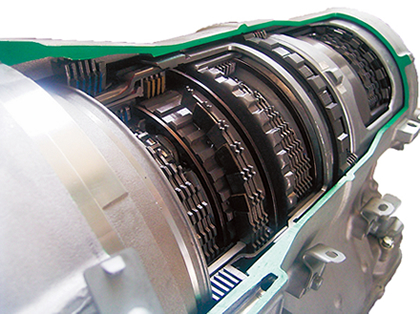

Paper is doing its part in one of Japan’s key industries, car manufacturing. The clutch in automatic transmissions uses thin steel discs to transmit the force of the motor, taking advantage of friction for automatic gear shifting. It was paper that inspired the idea, and the discs are actually covered with a friction material made out of paper. The material is first treated so that it readily absorbs oil and releases heat, giving it the ability to withstand wear-and-tear practically forever and perfecting a friction material that will last longer than the car itself.

Paper has an important role to play in agriculture, as well. In a Japanese orchard you are likely to see paper bags carefully protecting the fruit for a certain period of time before the harvest. One reputable manufacturer has made bags from traditional washi paper for more than 100 years, coating them with persimmon tannin. Today, its purpose-designed paper bags protect the fruit from wind, rain and insects while repelling water and maintaining just the right amount of ventilation. Moreover, baggies for apples, placed over the fruit a month before harvest, keep out excess sunlight to control the production of chlorophyll and give a brightly colored effect. Mangos are also covered with bags, which are double-glued at the bottom to prevent the fruit from dropping out when fully ripe. These are just two of the bag types developed specifically for each fruit.

In Japan, most orchards wrap each fruit in a paper bag to obtain optimum quality. (Photo: amanaimages Inc.)

New paper materials offer potential for a brighter future

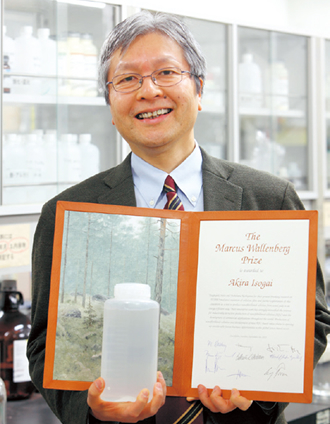

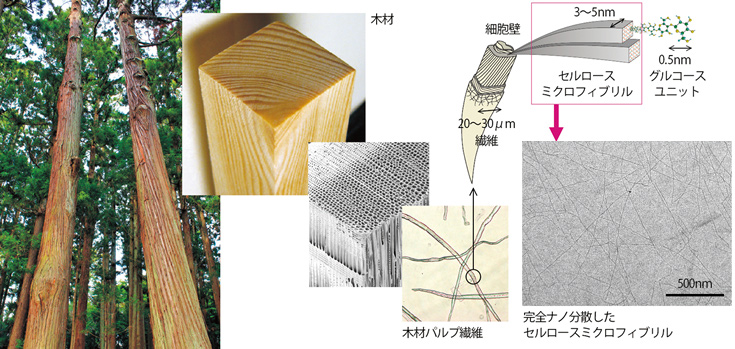

New materials are turning the whole idea of paper on its head, ever since Professor Isogai Akira of the Faculty of Agriculture at the University of Tokyo was awarded Sweden’s Marcus Wallenberg Prize, which is considered the “Nobel Prize” of the forestry industry. Many corporations and universities are conducting research in cellulose nanofibers, a structurally refined material obtained from wood fiber, but his research lab was the first in the world to succeed in using a special chemical reaction to break down wood pulp to the structural unit level of microfibrils, which form strong bonds within the cell walls of cellulose and tend to be difficult to separate. This success led to the creation of an entirely new type of cellulose nanofiber.

“Cellulose nanofibers are five times stronger than iron, and five times lighter. They can also incorporate many metal ions. These advantages have led to developments promoting the commercialization of ballpoint pens with dependable ink flow, and paper diapers with more than three times the deodorizing power,” explains Professor Isogai.

Because they have properties similar to carbon fiber, cellulose nanofibers show potential in the manufacture of aircraft and motor vehicles. And they hold the secret to achieving greater recycling and a more sustainable society by reusing wood from Japanese cedar and Japanese cypress trees, which make up about half of Japan’s forests.

“The knowledge built up by engineers in the paper manufacturing industry is now being transformed into new industrial know-how, thanks to Japan’s world-class, cutting-edge papermaking technologies,” says Professor Isogai with evident pride in his voice.

Paper has played an important role in the everyday lives and industry of the Japanese for more than a thousand years. Today, those techniques are moving in new directions for the benefit of future generations.

Cellulose nanofibers made by stripping microfibrils from the cell walls of wood cellulose, then breaking them down. The nanofibers hold much promise for a wide range of future developments.

Uni-ball Signo UMN-307 pens made by Mitsubishi Pencil Co., Ltd. The ink incorporates just the right amount of cellulose nanofibers for an even flow.