Web Japan > Trends in Japan > Fashion&Design > The Charm of Continuously Glowing Gold Leaf with a Thickness of One Ten-thousandth of One Millimeter

The Charm of Continuously Glowing Gold Leaf with

a Thickness of One Ten-thousandth of One Millimeter

Small boxes decorated with gold leaf (Owned by Kanazawa Yasue Gold Leaf Museum)

Due to its rarity and beauty, gold has in all times and places been revered as a symbol of prosperity.

Gold leaf, called kinpaku in Japanese, is a handicraft material that conveys the charm of gold in modern-day Japan in a refined and elegant form. Gold leaf is made by mixing gold with tiny quantities of silver and copper, and flattening it to the utmost extent.

Buildings and rooms are decorated with gold leaf, and so are the surface of art objects, tableware, writing utensils and more. Recently, it has become applied even to beauty products.

Artisanal Techniques Enable Extreme Thinness

Most Japanese gold leaf is made in Kanazawa City, Ishikawa Prefecture, located in central Japan. Gold leaf production in Kanazawa is assumed to date back to 1593.

The thickness of gold leaf is approximately one ten-thousandth of one millimeter. When one holds gold leaf up to sunlight, it acquires a mysterious blue shine. The extreme thinness of gold leaf is made possible by the astounding traditional production techniques acquired by craftspeople. About 60 such craftspeople are currently active in Kanazawa.

The process of making gold leaf begins with inserting sheets of pure gold called jigane into an oven heated to 1300 degrees Celsius. In order to flatten the gold neatly, small quantities of silver and copper are added and mixed with the gold at this high temperature to produce an alloy. The color of the gold leaf changes slightly depending on the quantities of silver and copper added at this point. The standard coloration is achieved using a distribution of 94.438% gold, 4.901% silver, and 0.661% copper.

After melting the hot alloy in the oven, it is transferred to a mold. The alloy is then flattened to about one twentieth of one millimeter, before being flattened even further through the processes of zumiuchi and hakuuchi. (Image supplied by the Ishikawa Prefecture Haku Leaf Commerce and Industry Cooperative)

This alloy is formed by machine into a belt with a thickness of about one twentieth of one millimeter, which is cut neatly into a square about five centimeters long. Sheet by sheet the alloy is then wrapped into washi (fibrous Japanese paper), stacked to a height of nearly ten centimeters and bound with leather straps. The craftsperson carefully flattens the bundle further little by little by repeatedly applying mechanical pressure from above.

The process by which the alloy is first flattened to about one thousandth of one millimeter is called zumiuchi, and that by which it is further reduced to one ten-thousandth of one millimeter hakuuchi.

The machine used for the final process of hakuuchi features a metal bar moving up and down 700 times per minute. The end of the bar presses down on the bound alloy from above, flattening it.

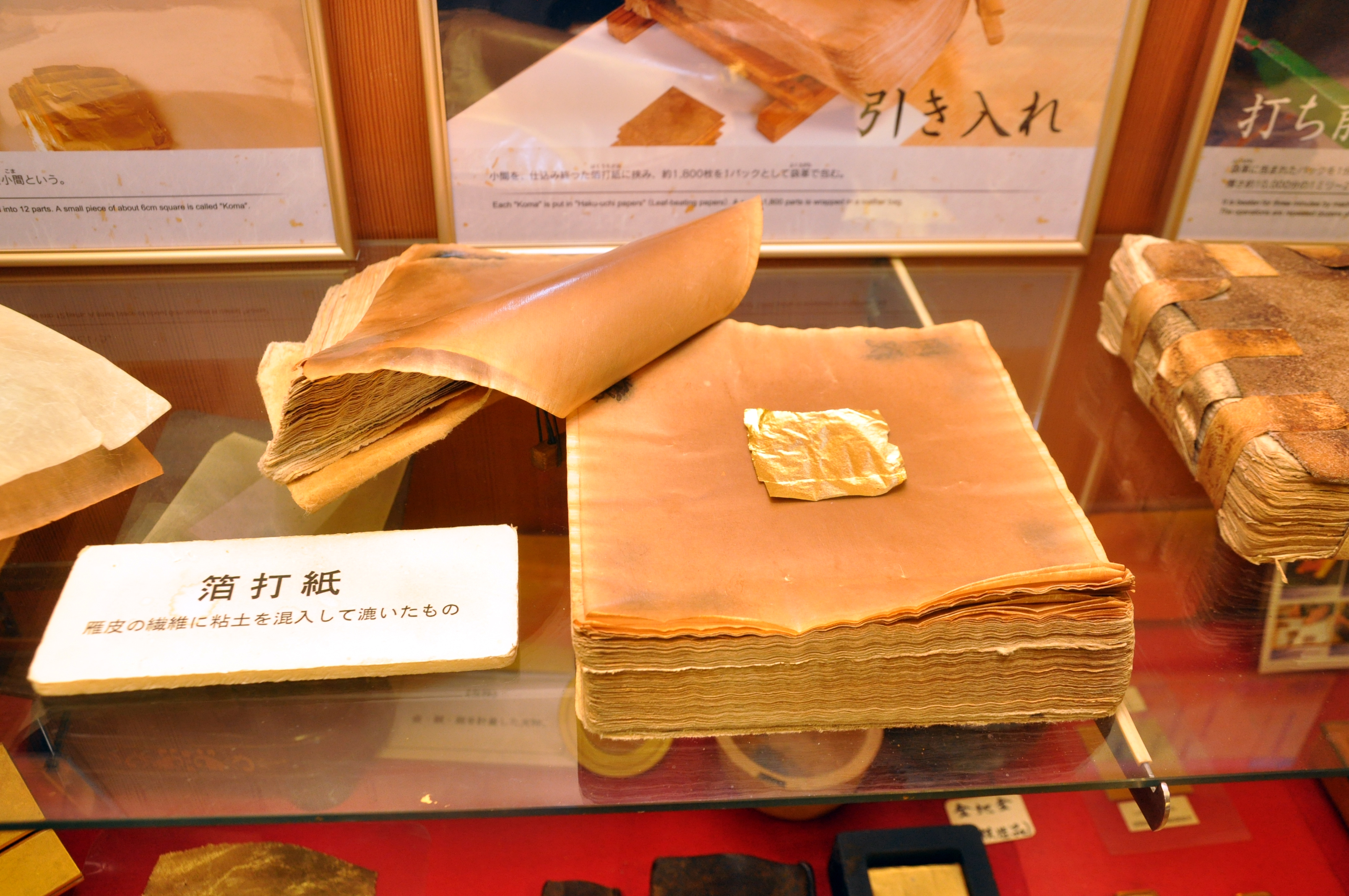

Hakuuchi Paper Determines the Quality of Gold Leaf

In order to flatten the gold leaf evenly, the craftsperson shifts the bundle slightly with every stamp of the metal bar.

The hakuuchi paper enveloping the gold leaf is extremely important. It is an improved version of handmade washi from Hyogo Prefecture and its quality determines the final grade of the gold leaf.

The paper is also painstakingly made by the craftsperson. Handmade washi is soaked in a liquid called akujiru, made from the cinders of dried rice plant stalk “rice straw,” and mixed with persimmon tannin squeezed from persimmon and egg, which permeate the washi. After the washi has been thoroughly soaked, it is firmly flattened out with a rolling pin and dried sheet by sheet. The washi is put into bundles of appropriate size and repeatedly stamped via machine to make its surface firm and smooth.

① Akujiru containing persimmon tannin and egg (Image supplied by the Kanazawa Gold Leaf Traditional Art Preservation Society)

② Soaking each sheet of washi with akujiru (Image supplied by the Kanazawa Gold Leaf Traditional Art Preservation Society)

③ Thoroughly permeating the washi with akujiru turns it into sturdy and smooth hakuuchi paper (Image supplied by the Kanazawa Gold Leaf Traditional Art Preservation Society)

④ Using a rolling pin to squeeze out the akujiru from washi soaked in it (Image supplied by the Kanazawa Gold Leaf Traditional Art Preservation Society)

Hakuuchi paper used to wrap gold leaf. A small square fragment of gold leaf rests on top (Sakuda Gold & Silver Leaf Crafts)

The above processes are repeated five to six times before the finished product is complete. Although the paper’s surface is smooth, it is so sturdy that it can be struck many times without tearing. Its smoothness is what enables the even flattening of gold leaf. Hakuuchi paper that has been worn out is turned into oil-absorbent paper used for adjusting makeup for sale. Thanks to its excellent absorbing qualities, the paper picks up oil and sweat, efficiently cleaning the face.

A Plethora of Applications

All sheets of finished gold leaf ready for shipping are square. There are four sizes, of 10.9 mm, 12.7 mm, 15.8 mm, and 21.2 mm. The appropriate size depends on the object to be decorated.

Gold leaf is attached using lacquer and similar adhesives. Due to its thinness, it can be neatly attached to even and uneven surfaces and it can be used with diverse materials, such as ceramics and glass.

Some folding screens used to divide or decorate rooms feature gold leaf sheets of uniform size to gild their entire surface. Such “gilded screens” have been employed as canvases for paintings since ancient times.

A gilded-screen painting showing “Views in and around the City of Kyoto” (17th century, Kanazawa Yasue Gold Leaf Museum)

Gold leaf, which evokes splendor, is often used for decorative lucky charms considered symbols of good fortune in Japan and other nations, such as owls or “Maneki Neko (beckoning cats)” raising their left or right front paw to invite financial fortune or customers. These are popular souvenirs among foreign tourists visiting Kanazawa.

Gold leaf is not only used for artistic and decorative objects, but also for tableware like containers, trays, and plates. Tableware decorated with gold leaf is often brought out for special occasions celebrating a family’s health and good fortune. Gold leaf is also used to beautifully decorate writing utensils and small boxes for accessories.

Recently, many beauty products containing gold leaf, such as skin lotion with pulverized gold leaf said to be beneficial for the user’s beauty, have appeared on the market.

Stores producing gold leaf in Kanazawa City offer the experience of attaching gold leaf to chopsticks or containers at a reasonable cost. Such opportunities are popular with tourists as a great way to experience the fascination of gold leaf firsthand.

In Kanazawa the charm of gold leaf naturally fuses with the town and everyday lives to this day, providing people’s daily lives with warmth and elegance.