No one likes the pain of injections, so Japan has developed a technology whereby injections do not cause pain.

Many people are bad when it comes to injections. Some dislike them so much that they come to hate hospitals. However, people not only require injections when they catch a cold or need a vaccination—there are some people who require injections every day. For example, diabetes patients have to regularly monitor sugar levels in their blood and inject themselves with insulin—not once, but several times a day. Thus, research on "painless injections" has been conducted to help such patients battle their diseases.

Ultra-fine Needles Enable Painless Injections

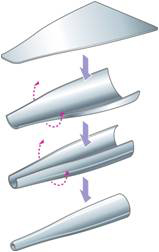

A single sheet of stainless steel is formed using a method that rolls each sheet into individual cylinders. The inside of the needle is carefully polished so that liquid can flow freely through it. (Photo courtesy of TERUMO CORPORATION )

There are two main factors that make injections hurt: one is the thickness of the needle—the thicker the gauge of the needle, the bigger the hole, hence the bigger the pain; the other is the friction factor of the needle—even if a needle is fine, its saw-tooth design causes pain because it damages the skin. Japanese technology took up the challenge to solve these two problems.

Basically, the finer the needle, the lesser the pain, but if the needle is too fine, it breaks. Thus, the need was to develop a fine needle with a structure that does not easily break. How to create a fine needle with such a structure was a mystery in the beginning.

The traditional method of manufacturing a needle is to roll a thin sheet of metal into a tube, and then draw the tube out to make it finer. However, there is a limit to the fineness that can be achieved using this method, and the product cannot be made fine enough to a point where the needle would not cause pain. A different processing method was conceived; however, no company that could process such fine needles could be found.

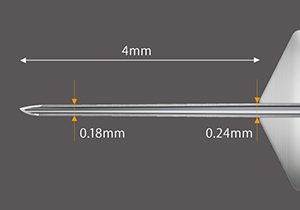

The needle has a wide base and narrow tip, allowing medication to be injected smoothly. (Photo courtesy of TERUMO CORPORATION)

An insulin needle as used by diabetes patients. The painless needle lessens the pain and fear of needles, and thus alleviates the suffering of patients. (Photo courtesy of TERUMO CORPORATION)

Just when people were giving up on this new process, a small-town factory raised its hand and said, "We will give it a try." Although this factory had never made needles before, hearing other factories label the process “impossible,” it decided to take up the challenge. The factory's specialty was press processing. Press processing is a technology that extrudes flat metal sheets into molds with indentations to create the desired shape. Press processing itself is not a new technology, but the factory had the technology to process extremely fine items, such as battery cases for mobile phones. After using the technology and challenging the idea countless times to improve the process, it finally succeeded in creating a needle that is fine, does not break, and securely delivers drugs.

Idea Based on Mosquito Proboscis

The idea for the needle was based on the proboscis of the mosquito, as you do not feel pain when it bites you. The mosquito's proboscis has very small saw teeth that seem to lessen the pain.

The painless needle above was made by imitating the saw teeth at the tip of the mosquito's proboscis. (Photo courtesy of LIGHTNIX, Inc.)

Fine needles that use the configuration of a mosquito’s proboscis were also developed. Even now, the reason a mosquito bite does not hurt is not fully understood. The fact that mosquito saliva contains an anesthetic and that the mosquito's proboscis is extremely fine have been cited as reasons. While these are not the only reasons, painless needles have been developed by applying currently known technologies.

One reason is the presence of ultra-small saw teeth on the tip of the mosquito's proboscis, which are now known to lessen pain. The shape looks painful, but the saw teeth in the proboscis, despite an appearance to the contrary, lessen pain. As the shape of these painless saw teeth were known, a design identical to those of the mosquito was incorporated into the needles.

Another reason is the use of plant resin as the needle's material. Plant resin is softer than metal, so the pain is less and, as they are disposable, they are sanitary and safe to use.

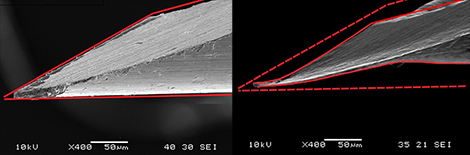

As the "painless needle" requires delicate processing, even small chips and cracks—let alone uneven surfaces—cannot be tolerated. If such imperfections remain, the hard-won technology does not live up to its expectations, and the pain will not be alleviated. Thus novel grinding technologies were developed and used to cleanly polish the surfaces.

Fineness, saw teeth to lessen pain, pain-free material, and smoothness achieved with the latest technologies—accumulating all these technologies—developed a needle with little pain. Hospitals are no longer scary, right?

Left, The needle before processing. Right, The needle after processing using the latest technology. The tip of the needle is extremely fine and smooth. (Photo courtesy of Mitsubishi Materials Corporation)