Sushi Party in Space

Freeze-drying is a method of removing frozen water in a material by allowing the frozen water to transition directly from a solid state to a gaseous state without ever becoming a liquid. This approach takes advantage of the fact that in a near-vacuum environment, water boils at temperatures of between minus 20 C to 30 C. Freeze-drying results in food that is one-quarter its original weight, that can be preserved for long periods of time without refrigeration and that retains its shape, color and nutrients.

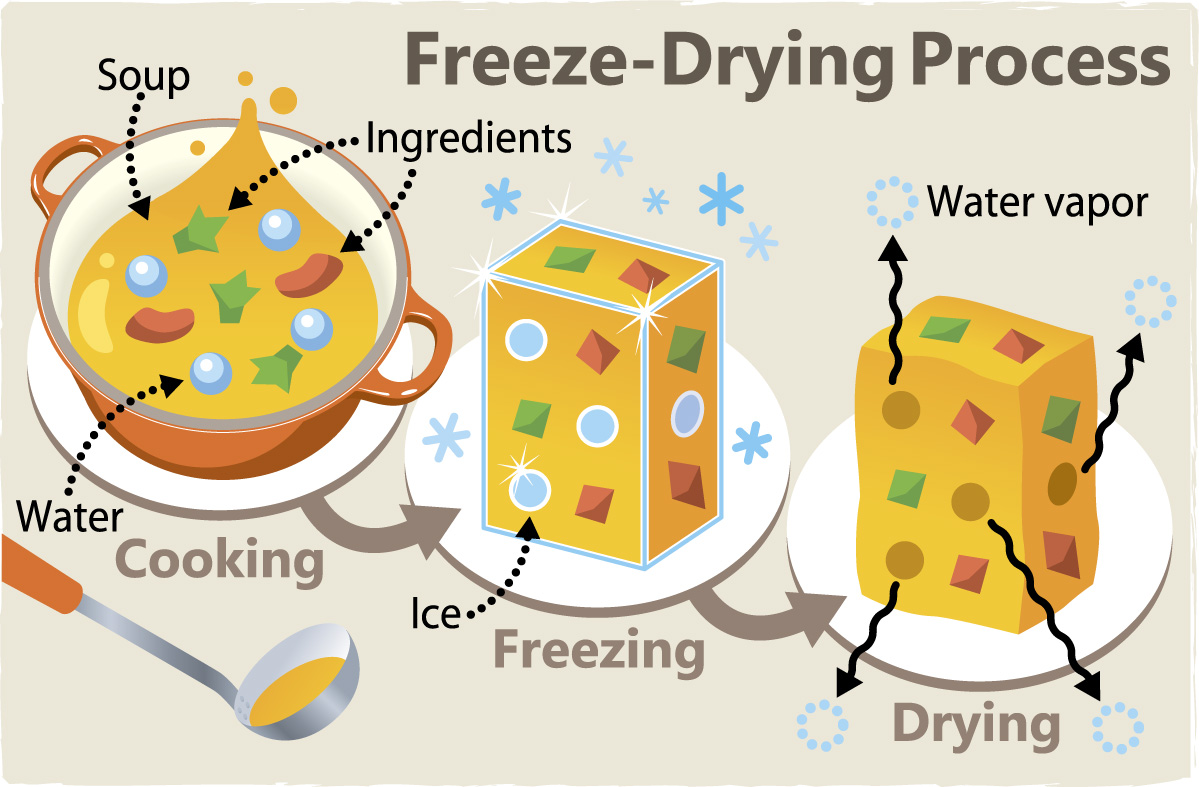

The freeze-drying process: 1) freshly made food contains much water, 2) the food is frozen at minus 30 C, causing the water to freeze, and 3) warmed and dried in a vacuum, the ice is released as vapor without turning to water.

Frozen tofu made the old-school way: freeze dried in the cold wind. (Photo courtesy of Osaki City)

Freeze-drying is a technology that was developed in Europe and that spread globally in the 20th century. A similar practice developed in Japan nearly 800 years ago is the traditional making of koridofu, or frozen tofu, which is made by freezing and drying tofu outside one’s home. It is a practice that has been handed down to date.

Freeze-dried foods appeared in Japan in earnest in 1971 when instant noodles – requiring just hot water and a three-minute wait – burst on the scene. Although the noodles are made using a different drying method, the other ingredients, such as shrimp, meat and eggs, are all freeze-dried. In the nearly four decades since the world’s first instant noodles were made in Japan, approximately 31.7 billion servings of the dish have been eaten in total in 80 countries and regions. In 2005, freeze-dried ingredients were used in the world’s first instant noodles for space carried on U.S. space shuttles.

Japan’s first instant cup noodle, eaten the world over now. © Nissin Foods Holdings Co.

Japan’s first instant cup noodle, eaten the world over now. © Nissin Foods Holdings Co. |

Astronaut Soichi Noguchi enjoys freeze-dried noodles on the International Space Station. (Photo courtesy of JAXA/NASA)

Astronaut Soichi Noguchi enjoys freeze-dried noodles on the International Space Station. (Photo courtesy of JAXA/NASA) |

On a space-related note, you may have heard about the Japanese sushi party in April 2010 held 400 km above Earth on the ISS. The raw fish used to make sushi by Japanese astronauts was freeze-dried like the food enjoyed by the Antarctic research expedition team. Each kilogram of payload that a rocket carries into space is said to come with a price on the order of several million yen, making all the more reason that the light, long-lasting and delicious freeze-dried Japanese foods have created ever-higher expectations among people working in space development.

Restoring Tsunami-Damaged Materials

Food manufacturing is not the only area in which freeze-drying technology is being put to use. It is also being used in the life sciences such as in pharmaceutical development as well as in the preservation of archeological materials excavated at ruins.

In Japan, thin wooden documents with letters in black ink, which are known as mokkan, have been found at numerous locations. Often times, these mokkan have been buried in soil or immersed in water and have swollen due to absorbed moisture. Simply heat them to dry them and they shrink. Freeze-drying technology is used to dry them while also restoring them to their original shape.

Work being done to restore items such as tsunami water-soaked cultural properties using the world’s largest freeze-drying device for academic purposes. (Photo courtesy of National Institutes for Cultural Heritage Nara National Research Institute for Cultural Properties)

Freeze-drying technology has also been used to restore items damaged by water as a result of the massive tsunami resulting from the Great East Japan Earthquake that struck in March 2011. Left untouched, cultural properties and important documents would at some point mold and disintegrate. However, the freezing component of freeze-drying prevents them from molding while the process also allows many documents to be dried at once without the danger of them being torn.

In this way, Japanese freeze-drying technology is playing an important role in supporting people’s lives around the world.

(February 2013)